General information

Purpose

Unloading of hoppers, filters, pneumatic units and other equipment operating both under overpressure and under exhaustion.

The rotary shutters of BARRIER-HERMETIC model are used to block access to the air unloaders or to prevent the escape of gases through the lower window of the unloading units of drying and dust-collecting plants. The rotary shutters of BARRIER-HERMETIC model are installed at the outlet of unloaders of pneumatic installations for bulk products, filters, cyclones and other machines in which the air pressure may differ from atmospheric pressure.

In addition to the sealing functions of unloading chambers, BARRIER-HERMETIC rotary shutters can also be used as drum (cell) feeders or volumetric dosing devices for controlled supply of powdery, granular, small-sized materials, including highly abrasive ones. The main distinguishing feature of BARRIER-HERMETIC rotary shutters is the cell rotor (for BARRIER-HERMETIC 20 model – rotor plates) made of one of the most durable polymeric materials — polyurethane.

Due to their unique performance characteristics, polyurethane elements today are increasingly replacing not only rubber but also metals in technical equipment. Where high wear resistance, strength, elasticity is required, polyurethane is a practically non-alternative material. Sieves for vibrating screens, protective wear-resistant coatings, shafts and rollers, cuffs and seals – far from being a complete list of products from abrasion-resistant elastomer – polyurethane. Now, thanks to the development of the engineering company TECHPRIBOR, the cell rotor of BARRIER-HERMETIC rotary shutter can be added to this list.

Benefits

- Tightness during all service life;

- Patented polyurethane rotor design;

- Stand-alone bearing supports;

- Gear-motor from a well-known international manufacturer;

- Low operating costs;

- Standard connections and manufacturing as per design assignment.

Specifications for BARRIER-HERMETIC rotary shutters

|

||

| Parameters | Values | |

|---|---|---|

| «BARRIER-HERMETIC 6» | «BARRIER-HERMETIC 20» | |

| Capacity, m3/h | 6* | 20* |

| Rotor diameter, mm | 263 | 410 |

| Rotor length, mm | 200 | 300 |

| Material of vanes | Polyurethanes | Polyurethanes |

| Material temperature, max. С° | max 70 | max 70 |

| Rotor hardness, Shore A, units | 85±2 | 85±2 |

| Rotor rotation speed, rpm | 14 | 18 |

| Drive power, kW | 0.55 | 1.5 |

| Overall dimensions (LxBxH), mm | 493 х 492 х 631 | 725 х 560 х 730 |

| Weight, kg | 58 | 180 |

Advice and technical support

The basis of high operational characteristics of the rotary shutters manufactured by TECHPRIBOR company, their great reliability and low operating costs is many years of experience and unique design solutions implemented in BARRIER-HERMETIC rotary shutters.

For the most efficient use of equipment in various production processes, the specialists of TECHPRIBOR are ready to provide technical support and advice, to develop unique components and parts.

A rotary shutter "BARRIER-HERMETIC 6". User manual. Passport.

A rotary shutter "BARRIER-HERMETIC 20". User manual. Passport.

Configuration and operating principle

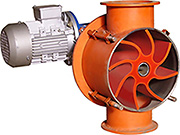

BARRIER-HERMETIC rotary shutters (Fig. 1) consists of a housing (1), a cell rotor (2), housing covers (3), a sealing device (4) and a gear-motor (5).

Fig.1

The material to be fed or dispensed fills the drum cells located at the top through the upper (loading) nozzle. When turning the rotor, the filled cells pass down, and the material is poured out through the lower (unloading) nozzle. The capacity of a rotary shutter depends, first of all, on volume of cells and rotation speed of the drum; accordingly, a change in the number of revolutions allows volumetric dosing of bulk materials in various production processes.

Advantages

When creating BARRIER-HERMETIC rotary shutters, the design department of TECHPRIBOR plant used a number of unique technical solutions aimed at improving operational properties of the equipment, increasing its reliability and durability. A short list of the main advantages of BARRIER-HERMETIC rotary shutter approves the above:

Polyurethane cast cell rotor – durability and tightness

The inner surface of the shutter housing, the vanes of the sector chambers are subject to abrasion, the intensity of which directly depends on the physical and mechanical characteristics of the material being transported and rotor speed. Cement, powdered lime, ash, slag, mineral powder, as well as a number of other bulk materials, for which the rotary shutters are required, are medium or highly abrasive. For this reason, the rotation speed of the polyurethane rotor of BARRIER-HERMETIC rotary shutter is only 14 rpm, and the vanes themselves are bent backward (relative to rotation of the rotor). Due to its elasticity, polyurethane vanes are always tightly pressed to the inner surface of the housing, ensuring the tightness of cells for the entire service life of the rotary shutter.

The inner surface of the shutter housing, the vanes of the sector chambers are subject to abrasion, the intensity of which directly depends on the physical and mechanical characteristics of the material being transported and rotor speed. Cement, powdered lime, ash, slag, mineral powder, as well as a number of other bulk materials, for which the rotary shutters are required, are medium or highly abrasive. For this reason, the rotation speed of the polyurethane rotor of BARRIER-HERMETIC rotary shutter is only 14 rpm, and the vanes themselves are bent backward (relative to rotation of the rotor). Due to its elasticity, polyurethane vanes are always tightly pressed to the inner surface of the housing, ensuring the tightness of cells for the entire service life of the rotary shutter.

Stand-alone bearing support – the key advantage of reliable operation without breakdowns and downtime

It is no secret that some manufacturers of rotary shutters, in pursuit of imaginary manufacturability and not significant savings in production costs, use the units where bearings and sealing elements are in a single housing. Such shutters are easier to manufacture, however, in practice, such solutions result in equipment downtime and the need for repair. The assemblies, the design of which does not provide for a possibility of visual monitoring of sealing elements condition, in the real production environment are simply doomed to periodic breakdowns caused by the ingress of transported material into the bearings.

It is no secret that some manufacturers of rotary shutters, in pursuit of imaginary manufacturability and not significant savings in production costs, use the units where bearings and sealing elements are in a single housing. Such shutters are easier to manufacture, however, in practice, such solutions result in equipment downtime and the need for repair. The assemblies, the design of which does not provide for a possibility of visual monitoring of sealing elements condition, in the real production environment are simply doomed to periodic breakdowns caused by the ingress of transported material into the bearings.

The specialists of TECHPRIBOR, understanding that the time lost during emergency repairs, replacing bearings, sealing elements and waiting for delivery of replacement parts is the lost time in production process, applied the unique configuration of stand-alone bearing supports.

In case when the tightness of a sealing element is disrupted for any reason, the transported material freely pours out of the housing, and does not fall into the bearings. Increased dusting or material accumulation during operation of the shutter can be easily detected even with a surface inspection of the equipment, and timely replacement of the sealing element will avoid serious damage. Thus, a fairly simple technical solution that makes it possible to visually check the seal condition reduces equipment downtime, saving both money and manpower.

Innovations for reducing operating costs

Despite the fact that polyurethane has a high resistance to abrasion and a low coefficient of friction, when working with abrasive materials, it is affected by natural wear. Certainly, compared with other designs, the polyurethane rotor lasts longer, but one day the moment comes when the rotor needs to be replaced, and here another important advantage of the new design is manifested – its cost-effectiveness!

Despite the fact that polyurethane has a high resistance to abrasion and a low coefficient of friction, when working with abrasive materials, it is affected by natural wear. Certainly, compared with other designs, the polyurethane rotor lasts longer, but one day the moment comes when the rotor needs to be replaced, and here another important advantage of the new design is manifested – its cost-effectiveness!

The rotors of conventional shutters are cast of steel and then machined on special metal cutting machines with minimal tolerances, because otherwise it is impossible to achieve tightness. The complexity of manufacturing dictates the high cost of such a rotor, another thing if the part is obtained by high-performance injection moulding, and its further processing is not required at all. Moreover, thanks to the elastic vanes, the shutter tightness is higher than that of analogues with steel rotors.

Having a longer service life compared with steel rotors of old design rotary shutters, polyurethane rotors are yet cheaper than those. A cast polyurethane rotor – not only tightness and a long service life, but also cheap consumables the price of which will not hit your wallet.

Selection of a rotary shutter

A. General Information

The machinery manufacturing plant TECHPRIBOR develops, manufactures and sells the rotary shutters of BARRIER-HERMETIC 6 and BARRIER-HERMETIC 20 models.

Design features of BARRIER-HERMETIC 6 rotary shutter: polyurethane rotor, housing cover with option of adjusting the end clearance, stand-alone bearing support, gear-motor filled with synthetic lubricant.

Design features of BARRIER-HERMETIC 20 rotary shutter: interchangeable rotor vanes made of polyurethane, housing cover with option of adjusting the end clearance, stand-alone bearing support, gear-motor filled with synthetic lubricant.

B. Drive station

BARRIER-HERMETIC 6 and BARRIER-HERMETIC 20 rotary shutters manufactured in TEHPRIBOR plant are equipped with high-torque gear-motors (international manufacturer) that ensure the long-term operation of the drive station – (8-24) hours a day when operating in S 1 operation mode (GOST 28-173). The main characteristics of used gear-motors are shown in Table No. 1.

| Model of rotary shutter | «BARRIER-HERMETIC 6» | «BARRIER-HERMETIC 20» |

|---|---|---|

| Gear-motor type | XC-75 | XC-110 |

| Rotation speed, rpm | 14 | 18 |

| Maximum torque, Nm | 255 | 454 |

| Electric motor power, kW | 0.55 | 1.5 |

C. Capacity and service life

The capacity of the rotary shutters depends on a number and volume of cells, a number of revolutions of the rotor, as well as the loosening coefficient of material (or the filling factor of the cells). The lower the rotor speed, the higher its filling with the material.

The wear resistance of the inner surface of the shutter housing mainly depends on the properties of the material being moved through and the rotor speed. In the rotary shutters of BARRIER-HERMETIC model, the rotor speed is only 14 rpm, which ensures a long service life of the shutter even when working with highly abrasive materials.

The capacity of BARRIER-HERMETIC 6 and BARRIER-HERMETIC 20 rotary shutters (for cement) is 6 m3/h and 20 m3/h, respectively.

D. Available nozzles configurations

The configuration of the unloading and loading nozzles, BARRIER-HERMETIC 6 and BARRIER-HERMETIC 20 rotary shutters, can be a standard design (Fig. 6) and can be changed according to customer’s specifications.

E. Overall dimensions

Е. Additional options

The rotary shutters produced by TECHPRIBOR machinery manufacturing plant can be equipped with electric current frequency converters at customer’s request, which allows using the rotary shutters of BARRIER-HERMETIC 6 and BARRIER-HERMETIC 20 models as volumetric dosing devices for bulk materials.

Patents and certificates

The rotary shutters of BARRIER-HERMETIC series were awarded with the diploma “100 Best Goods of Russia” program in 2012.

BARRIER-HERMETIC rotary shutters were recognized by rewards of international exhibitions.

The rotary shutters of BARRIER-HERMETIC comply with the requirements of Technical Regulation of Customs Union TR CU 010/2011 “On Safety of Machines and Equipment”. (Declaration of conformity EAES No. RU D-RU.MO10.V.04609 dd. 15.01.2018.)

Unique design solutions used to create the rotary shutters of BARRIER-HERMETIC are protected by RF patents for utility model No. 90426 and 109455.